Unlock the Full Potential of Your Operations

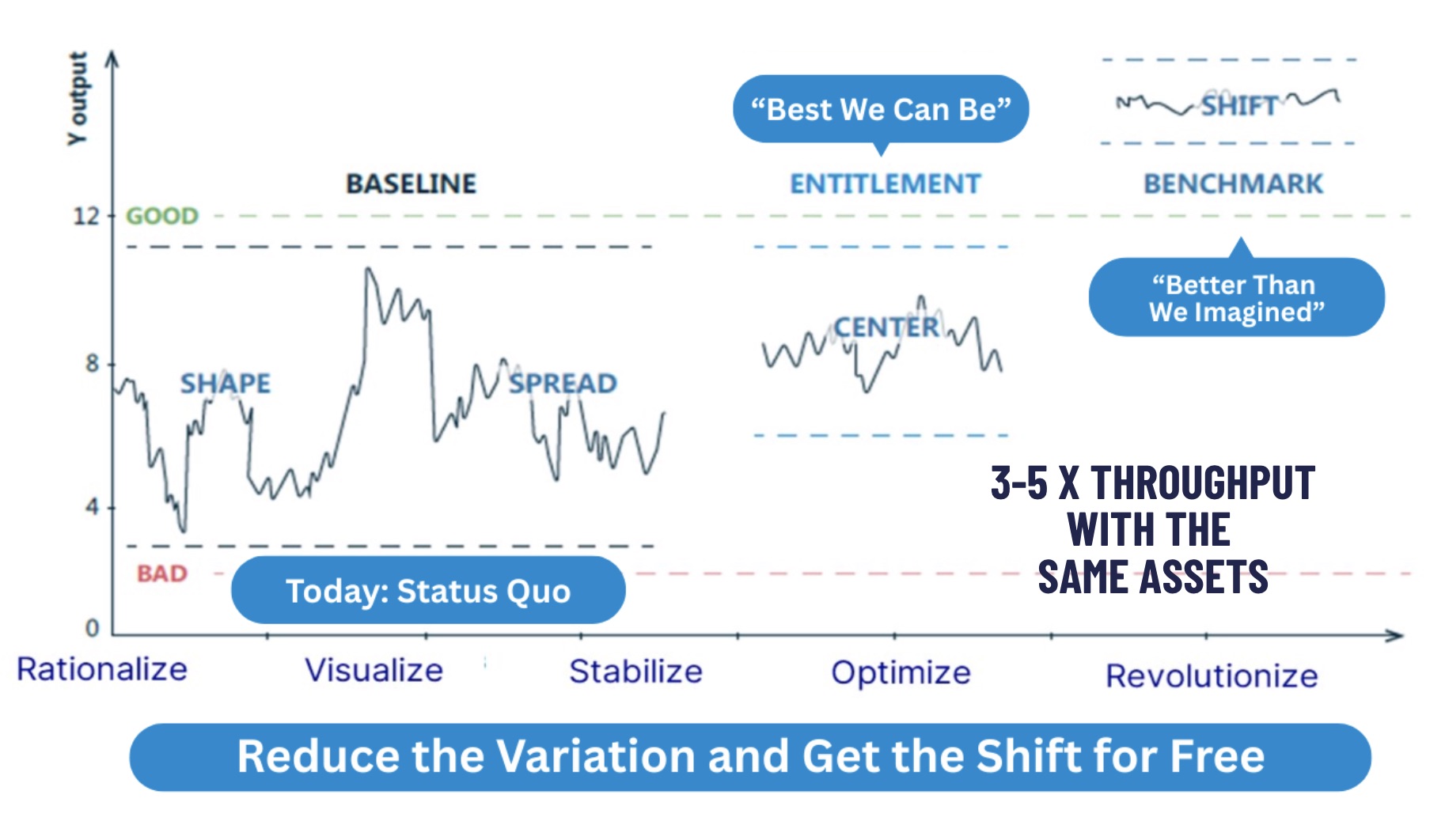

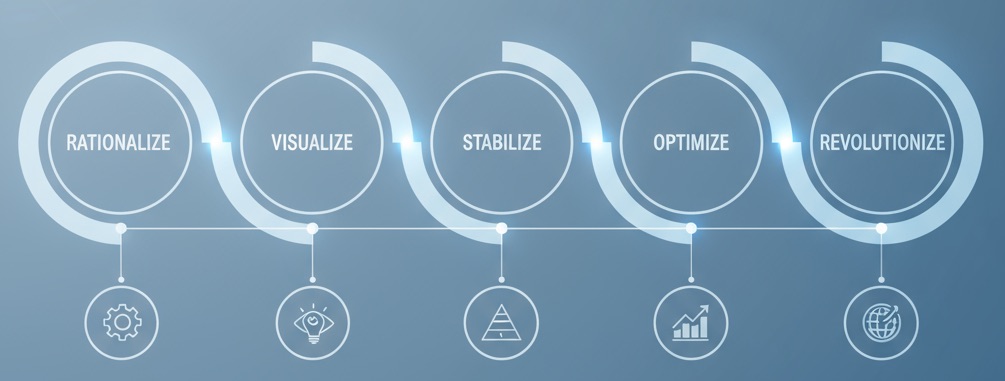

Optimal Ops™ helps leaders clearly see where performance drifts, uncover lost throughput, and maximize return on invested capital with AI-enabled visibility and continuous optimization.

Limited to 5 sessions per month – no obligation.